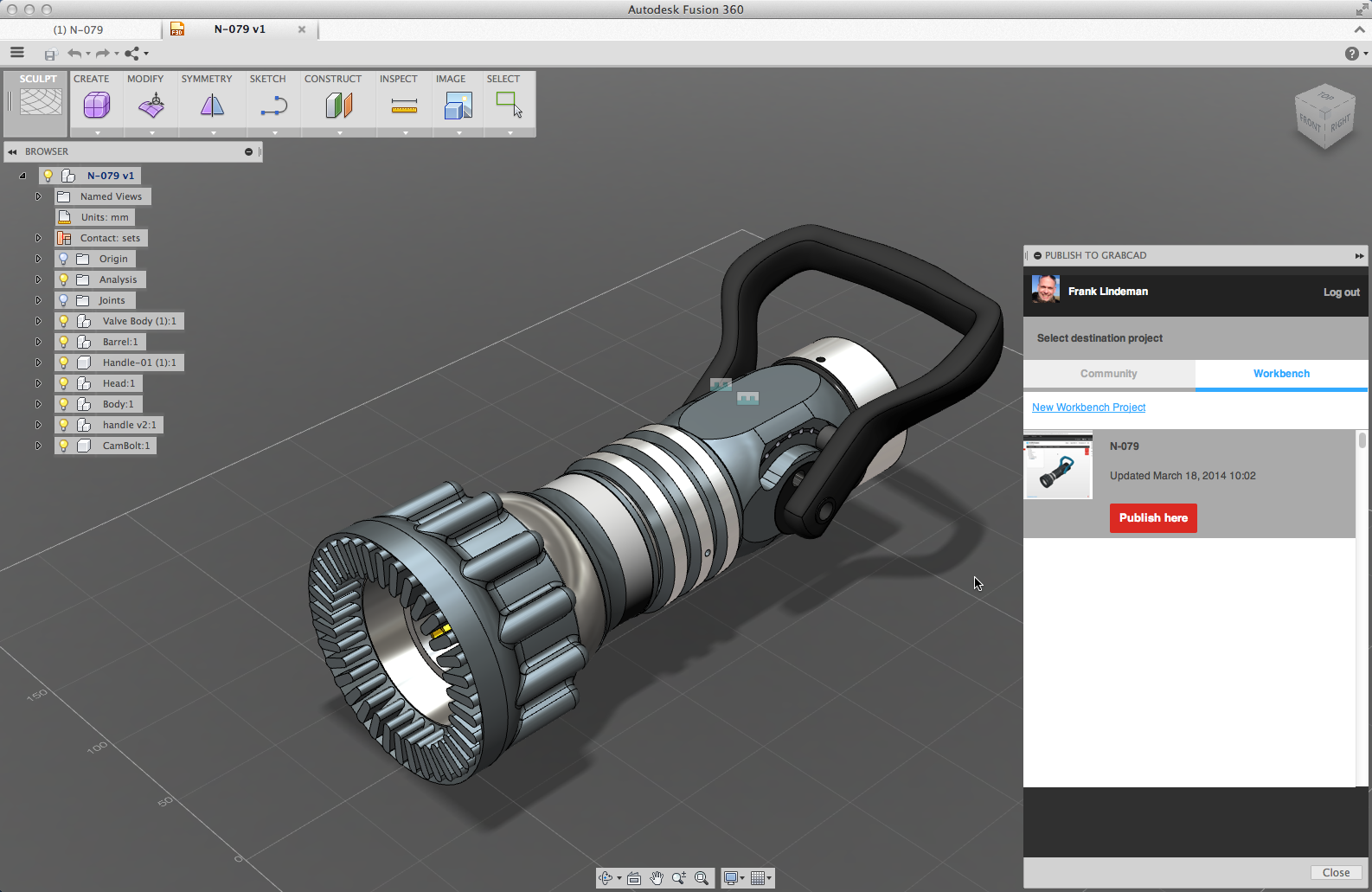

Here then is my recipe for creating v-carve inlays in Fusion 360. So when questions started coming up about Fusion in this forum, I dug my heals in and figured it out. But it bugged me that I couldn’t do the same in Fusion. It only takes me about a minute once I have artwork I like. Turns out, with their Advanced V-Carve function the inlays are trivial to set up. After failing to get a simulation that worked after several tries, I switched to Carbide Create, a free tool from Carbide3D. I quickly discovered that v-carve inlays are not so easy in Fusion. Since I’ve been using Fusion 360 free for a couple of years now it was my tool of choice.

Most of the time the YouTubers used Aspire. They look pretty cool so I thought I would try to create one. Our next test cut was far more successful.I was looking at YouTube videos that make v-carve inlays. Unlike the other explanation text, this doesn’t mention the setting as a potential compensation to lack of machine rigidity, but it worked.

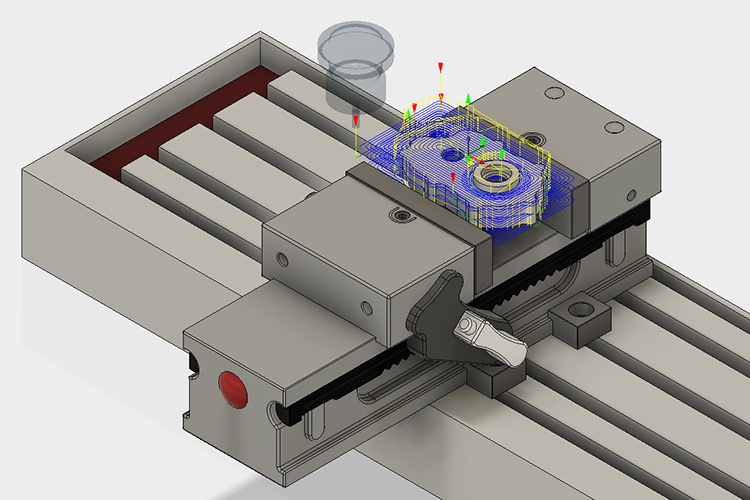

To tell Fusion 360 to take shallower passes, we can select the “Multiple Depths” option. Making full use of all cutting surfaces on the tool is a reasonable default, but that involves removing far too much material at once for our mill. We also wanted to take shallower cuts in the material, as by default Fusion 360 generates code to tell the CNC to plunge into full cutting depth of the cutter. Most real CNC mills in operation today are rigid enough for climb milling, so this was a reasonable default value for Fusion 360 to use, just not for us.

Our machine is not rigid at all by CNC mill standards and must be switched over to “Conventional Milling”. Key phrase in that explanation: This generally gives a better finish in most metals, but requires good machine rigidity. But what if we didn’t even have that much knowledge? Thankfully Fusion 360 included a brief explanation accompanying many settings, including the “Sideways Compensation” parameter relevant here.

We’re not professional machinists, but we knew enough to know this is not a good way to go for this machine. Looking over parameters for tool path generation, the first item we noticed is the default of “Climb Milling”. We now need to tell Fusion 360 how to be kinder to it. We know our project machine, built mostly out of salvaged parts, is not a CNC powerhouse. In parallel with investigating points of weakness within the physical structure, we’re also learning how to make Autodesk Fusion 360 CAM friendlier to hobbyist grade CNC mills.

0 kommentar(er)

0 kommentar(er)